- Burton: 01283 512866

- Bridlington: 01262 602467

email: will@sealandpump.co.uk

email: will@sealandpump.co.uk

In order to ascertain the best way for you to save money on your bills, our engineers that are trained to undertake pump energy audits that will check the current installed solutions, energy consumptions and related CO2 emissions, and offer a savings proposal that will produce a complete pump solution. Where necessary our engineers may also utilise a pump audit tool and data loggers to obtain the exact data from the current solution.

Out of sight but hard at work, pumps are everywhere around us. They are essential in every kind of buildings and installation whether it is industrial, water utility, commercial, public or private. It is fair to say pumps underpin our standard of living.

Pumps are truly the hidden heroes in our world today. We cannot move liquid efficiently from A to B without them. They assist in supplying us with the water we drink, heat and wash with and the food we eat. They send our wastewater away for treatment and are used to produce all the goods we buy and in the services we depend upon daily. Not surprisingly, enormous amounts of electrical energy are required to keep them all going.

The industrial sector is the largest employer of pumps, but all other building types, from hotels to hospitals to private homes, also depend on them for comfort and sanitation.

It is estimated that 2/3 of the pumps use up to 60% too much energy. So when you think about how pumps are everywhere around you, it is easy to appreciate the huge energy savings opportunity they present.

PepsiCo Roha in Maharashta, India commissioned a Pump Audit as part of their energy conservation initiative. The audit results highlighted an over consumption of energy and noticeable water wastage. As a consequence PepsiCo Roha decided to replace existing critical systems with energy efficient pumps.

On recommendation, vertical pumps and closed couple end suction pumps were installed in the utility and process systems in order to optimise the water-energy performance. The following models were used:CRN 64-2, NB 125-200/221, and NB 100-200/170, CR 20-03, and CR 15-04.

The result was easy installation, trouble free operation and reliable performance. PepsiCo Roha recorded a 41% reduction in energy use compared with the old pumping system with a monthly energy saving of 5625 kWh units. Maintenance officials stated that this positive experience has contributed to PepsiCo Roha's initiation into energy conservation and ensured quality production due to the efficiency and reliability of Grundfos pumps.

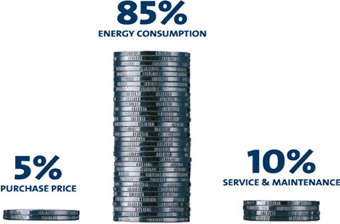

85% of the pump life-cycle cost is related to the daily operation of the pump?

Discover potential Energy Savings on your pump operations

Up to 4% of the world's total electricity consumption could be saved with the use of high-efficiency pumps